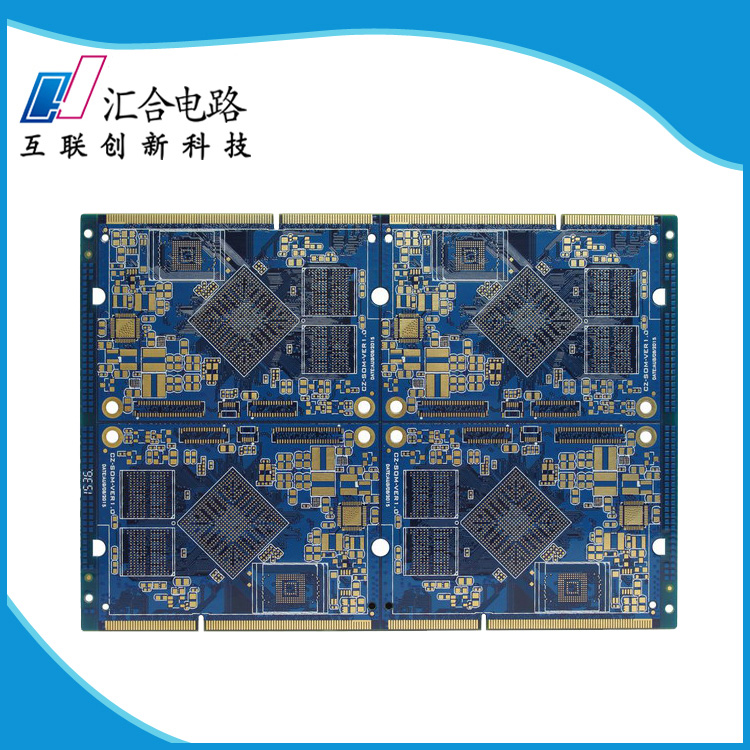

汇合电路是专业的线路板打样服务商,专注于高精密多层板、特种板的研发,以及pcb打样和中小批量板的生产制造。最近许多客户向我们咨询:如果PCB选材不一样,是否有不良的影响?

首先,通过线路板打样出的印刷电路板的信号具有依赖于印刷电路板的介电常数的速度。例如,当信号频率超过5 GHz时,FR- 4的典型介电常数(约4.7)下降到接近4。然而,罗杰斯RO4350材料的相对介电常数从0到15 GHz是恒定的(大约3.5)。如果印刷电路板的介电常数相对于频率变化,那么信号的不同频率分量将具有不同的速度。这意味着,这些组件将在不同的时间达到负载。结果,这会导致数字信号的失真。

Secondly, the signal losses due to printed circuit board material increase with frequency. Again, each harmonic of the digital signal will be attenuated according to that frequency of operation. Increased loss of the signal components will add to the distortion of the digital signal.

其次,由于印刷电路板材料的信号损失随频率增加。再次,数字信号的每一个谐波将根据该操作频率衰减。信号分量的增加会增加数字信号的失真。所以,线路板打样的选材会影响线路板质量。

Printed circuit board layout is often the single most important factor affecting the electromagnetic compatibility of electronic systems. Boards that are auto-routed or laid out according to a list of "design rules" do not usually meet electromagnetic compatibility requirements on the first pass; and the products using these boards are more likely to require expensive fixes such as ferrites on cables and shielded enclosures. Taking the time to ensure that components are properly placed and traces are optimally routed will generally result in products that meet all electromagnetic compatibility and signal integrity requirements on time and on budget.

因为印刷电路板布局往往是影响电子系统电磁兼容性的最重要的因素。根据“设计规则”列表自动布线或布置的板通常不满足第一道次的电磁兼容性要求;使用这些板的产品更可能需要昂贵的修复件,例如在电缆和屏蔽外壳上的铁氧体。花时间来确保组件被适当放置,并且轨迹被最佳路由,通常会导致产品在时间和预算上满足所有电磁兼容性和信号完整性要求。这也表明线路板打样的选材尤为重要。

相关阅读:影响PCB打样厂生产电路板可焊性的因素《二》【汇合电路】

扫描汇合电路服务号,更多汇合趣事等你来了解

汇合电路服务号

扫描汇合电路微信小程序,获取更多PCB资讯